RFID in Retail

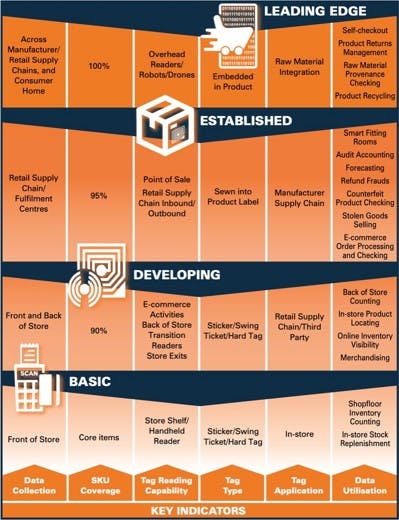

This Working Group is focused on understanding how the demands of Omni-channel retail operating environments increasingly require retailers to deploy a range of approaches to better identify and actively track products across their inventories and supply chains.

Looking particularly at technologies/approaches such as Radio Frequency Identification (RFID) and QR Codes, the Group is driving a research agenda focussed on developing not only a better understanding of how they can be effectively introduced and managed, but also what the current and emerging business cases are across various types of retail environment.

Research papers

Our research papers offer groundbreaking insights and actionable outcomes to help retailers and their partners better manage the many ways in which profits can be negatively impacted by all forms of retail loss. Produced by some of the leading academic experts in the field of retailing and loss prevention, they are all free to download.

Our Meetings

ECR Retail Loss Group regular working group meetings provide an opportunity to network with industry peers, hear updates on the latest research and sector initiatives, and development new skills and insights. All retailers, CPGs and academics can participate at no cost.

Blog RFID in Retail

Podcast RFID in Retail

What is RFID?

Radio Frequency Identification, or RFID technology uses radio waves to identify and track tags attached to products automatically.

It enables real-time data on inventory movement, allowing for precise tracking from warehouse to store.

Unlike traditional barcodes, RFID tags don’t require line-of-sight scanning, enabling faster, more accurate stock checks and reducing human error.

RFID is an important tool for streamlining stock management, minimising retail loss and improving operational efficiency.

How does RFID in retail work?

RFID tags on products contain unique identification codes. Readers use radio waves to capture this information.

These readers can scan multiple tags at once, making RFID highly efficient for tracking inventory in large retail environments.

A central software system processes the data as items move through the supply chain—from the manufacturer through the distribution centre and onto the shelf.

The technology allows retailers to automate processes such as self-checkout and loss prevention, preventing out-of-stock and overstock situations.

What are the retail benefits of RFID?

For loss prevention experts, RFID boosts stock visibility, helps identify shrinkage points, reduces theft, and improves overall inventory accuracy.

Our studies in the field of RFID have allowed us to help quantify the many retail benefits of RFID.

● Increased Sales: In our recent survey, 7 out of 10 retailers reported a sales uplift of between 1.5% and 5.5% as a result of using RFID, worth €1.4 to €5.2 billion.

● Improved Inventory Accuracy: RFID’s real-time tracking, boosts accuracy from around 70% to over 93%-98%. So retailers always know what’s in stock.

● Stock Availability: Improving inventory visibility reduces out-of-stock situations. So retailers using RFID can enjoy SKU (stock-keeping unit) above 90%.

● Reduced Stock Holding: RFID can cut the need to hold excess inventory. Half of the retailers in our case study reported a stock reduction of between 2% and 13%.

● Lower Stock Loss: Better tracking can prevent theft and internal loss. One retailer suggested their RFID helped cut its shrinkage losses by 15%.

● Reduced Staff Costs: Automated inventory checks are faster than manual stock counts, saving up to 4% on associated costs and freeing staff to focus on customers.

● Return on Investment: All retailers reported a solid return on ROI and were enthusiastic about rolling RFID out across their companies.

How is RFID shaping omnichannel retail?

By providing seamless inventory visibility across all sales channels, RFID allows retailers to track products in real time.

This enables accurate stock levels to fulfil online orders, in-store pickups, and deliveries. RFID also helps eliminate out-of-stock issues and mis-picks.

The technology provides a bridge between e-commerce channels and physical stores, making omnichannel operations more efficient, transparent, and profitable.

So your customers can have confidence that the product they’ve ordered is ready and waiting for them.

How do retailers use RFID?

Our research found that apparel retailers have been at the forefront of adopting RFID technologies. They primarily use it to track products across their supply chains.

RFID enables fast, accurate stock counts in stores. Attaching tags at the manufacturing stage is one of the most reliable and cost-effective methods.

Recent advances in the technology mean RFID tags can be applied to grocery items, such as meat or other fresh produce.

We spoke to two retailers undertaking RFID trials on the fresh meat category. Both were able to demonstrate 95%+ read rates. Their success is likely to lead to many more use cases.

What’s the future of RFID in retail?

RFID has a promising future as more retailers recognise its potential beyond traditional inventory management.

Innovations identified in our study allow businesses to integrate RFID more deeply into their operations, with benefits extending to supply chains, customer service, and loss prevention.

One respondent reported that RFID-enabled smart fitting rooms inspired the biggest leap in their net promoter score (NPS) of any of their current customer-facing digital tools.

We see retailers using the tech to streamline audits and improve store processes, leading to a more efficient and data-driven retail environment.

Another significant trend is the role of RFID in enhancing omni-channel shopping. As online sales continue to grow, retailers are using the tech to manage inventory more effectively across physical stores and digital platforms.

How can RFID tunnels boost warehouse operations?

RFID tunnels can significantly enhance warehouse operations by automating the scanning process of many items at once.

These tunnels are equipped with RFID readers that quickly capture data from multiple tagged products as they pass through, without needing manual scanning.

The ability to scan items in bulk has the potential to reduce the time and labour costs associated with manual counting and verification.

We are conducting research to understand the use of and the benefits of this and other approaches to reading RFID in warehouses.

How can RFID streamline self-checkout?

Using RFID at self-checkout to deliver a seamless shopping experience requires a 100% SKU tagging strategy, with extremely high read reliability.

Any tags not automatically read could lead to a direct loss to the business. However, the successful use of RFID to facilitate SCO was found to deliver several benefits:

● Speed of Checkout

● Loss Control

● Customer Service Benefits

The resulting near frictionless RFID checkout experience will require no scanning, no hard tags to remove and exit gates informing the customer what has and hasn’t been scanned.

Our research and meetings will investigate how retailers are moving towards this goal and share learnings on operationalising self-checkout.

What are Digital Product Passports and how can RFID help?

The EU’s Digital Product Passport rules take transparency to a new level. It’s a record that follows all goods from production to purchase. And even on to their eventual disposal.

Any company selling products in Europe will need to collect and share data on an item’s verified sustainability attributes.

Digital Product Passports are increasingly important for retailers promoting sustainability and circular economies.

RFID technology plays a crucial role in enabling Digital Product Passports by offering a seamless way to track and store product-specific data.

Our research and meetings will help keep retailers on track towards compliance in 2027. We’ll explore the business case and developments such as the use of smart devices to read RFID tags.

How do I join the RFID Working Group?

If you would like to join dozens of other retail loss experts on our RFID Working Group, we would like to hear from you.

To take part, email colin@ecrloss.com

FAQs RFID in Retail

The same research was also able to quantify some of the value that the participating retailers were prepared to share:

Increase in Sales: Seven of the 10 case studies shared data showing a sales improvement in the range of 1.5% to 5.5%. For SKUs identified by RFID systems as being out of stock, the growth was even higher. Based upon this data, the 10 companies taking part in the study may have realised an RFID-driven sales uplift of between €1.4 and €5.2 billion.

Improved Inventory Accuracy: Companies typically had an improvement from 65%-75% to 93%-99%.

Stock Availability: Some of the companies taking part were now findings SKU availability in the high 90% region.

Reduced Stock Holding: One-half of the case-study companies shared data on this measure, indicating a stock reduction of between 2% and 13%.

Lower Stock Loss: One company suggested that their shrinkage losses had been reduced by 15%.

Reduced Staff Costs: One company had measured a saving equivalent to 4% of their store staffing costs, which if rolled out across the case-study companies would be in the region of €378 million.

Return on Investment: All 10 companies were unequivocal in their assertion that the ROI had been achieved, and based upon their trial experiences, further roll out across the business was fully justified and embraced by the rest of the business, often with considerable enthusiasm and optimism.

Retailers are primarily, but not exclusively, interested in using RFID to identify products across their supply chains to improve the accuracy of their stock inventories. Thus far, most retail users of RFID have employed RFID to enable products in retail stores to be accurately identified and counted more quickly and on a more regular basis. Some retailers use RFID to track the shipment of goods from suppliers and within their own organisations. In addition, RFID can be used to monitor the movement of other retail assets such as pallets and delivery crates as well as promotional materials. For the most part, retail users of RFID seek to have the taggant attached to their products when they are manufactured (known as source tagging) as it is typically a more reliable and cost effective method than applying it within the retail supply chain or at a retail store. Retailers will then make use of fixed and handheld readers to identify their stock at various locations, such as in a warehouse, entering the back of a store, and when it is on a store shelf. Key to the use of RFID is a database management system that enables the unique product codes to be associated with any given item. These systems can provide powerful business intelligence such as the location of any given product and its current status (such as sold or unsold).

Recent research by the ECR Retail Loss Group identified the following reasons why retailers were investing in RFID:

Driving Sales: The primary goal of investing in RFID was to deliver improvements in inventory visibility and accuracy, which in turn would grow sales.

Optimising Stock Holding: Respondents also recognised the potential of RFID to enable them to optimise their stock holding, reducing capital outlay and improving staff productivity.

Fewer Markdowns: Most case-study companies regarded RFID as a key tool in helping to reduce the amount of stock they offered at discounted prices.

Helping to Drive Innovation and Business Efficiencies: RFID was frequently viewed as part of a broader organisational change project focussed on putting enabling technologies in place to drive transformational change to achieve future success.

Recognising the Omni Channel Imperative: This technology was viewed as a key driver in developing the capacity to deliver a profitable omni-channel consumer experience – in effect the organisational ‘glue’ that will hold together much of the architecture of 21st Century retailing.

Click here for the report

RFID is an acronym for Radio Frequency Identification. It is a technology which makes use of some form of taggant attached to an antennae (such as a label or physical tag) to encode data that uniquely identifies the item to which it is attached. This data can then be captured via radio waves by different types of powered reader devices. While similar in purpose to a barcode, RFID is seen to have at least two big advantages – the ability to identify objects uniquely (such as via an Electronic Product Code) and the capacity to do this without the need for line-of-sight (unlike a barcode). It is a technology that is used in a number of different settings, such as libraries, collecting road tolls, tracking and identifying animals to name but a few. Its use within retail can be tracked back to the late 1990s/early 2000 when initiatives such as the MIT AUTOID Centre began to develop standards and technologies suitable for use on a wide range of retail products.

The ECR research found that retailers were looking at the following areas as potential areas for further developing their use of RFID:

Using the technology in fitting rooms and with ‘Magic Mirrors’; greater use of RFID along the entire supply chain; broadening coverage across more SKUs and locations; improving data collection interfaces and data integration in the business; improving tags, in particular how they are attached to various products; exploring how overhead readers may be used in the future; delivering checkout-less stores; and creating seamless merchandise visibility with a range of technologies beyond just RFID.

One of the great challenges of managing retail loss is the lack of precise data on its causes, making the development of ameliorative actions more akin to guesswork than calculated intervention. The reason why the causes of most losses remain unknown is due to the way in which loss or ‘shrink’ data is often generated.

Typically, a retailer’s shrink number will be calculated when periodic physical stock audits are undertaken, which reveal the difference between the amount of stock (either in terms of value or number of items) the system thinks the business should have on hand (based upon the difference between the amount of stock acquired versus the amount sold through checkouts), and what is actually present. The discrepancy is ‘shrink’, often expressed as a percentage of the total amount. So, a company that buys 100 units and sells 80, with 10 remaining in stock has a shrink rate of 10% – 10 items have gone missing. Because there is very often a time lag between when an item has gone missing and when a physical audit takes place that recognises the loss (for those undertaking annual audits, it could be up to a year), it can be very difficult to know why it happened. Did the item ever arrive at the store? Was it returned to the supply chain but the transfer not recorded? Did a customer steal it? Did a member of staff steal it? There are many reasons why losses may occur but very often because of the data time lag, ascertaining the root cause is almost impossible. Given this, the potential for RFID systems to generate stock level data much more frequently and potentially enable awareness of product location, could mean that those responsible for loss prevention should have better quality data to understand how losses are affecting a retail business and build better strategies accordingly.

In addition, some retailers are now beginning to use their RFID systems to identify when a Returns Fraud is occurring. This happens when a thief returns an item that was originally stolen for a refund. Because existing barcode technologies do not record whether any given product has been sold or not (it simply identifies it as a particular type of product), then thieves can exploit the refund process and request cash or credit for items they did not originally purchase. The benefit of RFID is that because each product is uniquely identified, and its status potentially recorded in a database, then a member of staff working on a refund desk can be in a much clearer position to decide as to whether it is appropriate or not to issue a refund.

In a similar vein, some retailers have been using their RFID systems to generate an alert when an unpurchased product leaves a store (operating in a similar way to EAS tags, described elsewhere in this FAQ). Again, the big advantage of RFID in this scenario is that there is the potential for the alarm responder to be made aware of which particular product has triggered the alarm, something that most existing EAS systems cannot achieve. This then makes the stop and enquire process much quicker and more focussed. However, some retailers that have tried using this functionality of RFID have run into difficulties around read accuracy for certain types of tag, and of course, where the tag is merely a paper label, then the thief can simply remove the tag before exiting the store.

Finally, some retailers have argued that they purposefully do not want their RFID tags to be viewed as a security tag – the primary benefit of RFID to them is to improve stock accuracy and so this could be compromised if thieves begin to actively remove tags in order to evade detection. This can of course be dealt with to a certain extent by the application of hard tag RFID technologies, but this brings with it additional tag application and management costs that could undermine the ROI business case for introducing RFID in the first place.

Main office

ECR Community a.s.b.l

Upcoming Meetings

Join Our Mailing List

Subscribe© 2023 ECR Retails Loss. All Rights Reserved|Privacy Policy